SERVO PRESS SYSTEMS

About Servo Presses

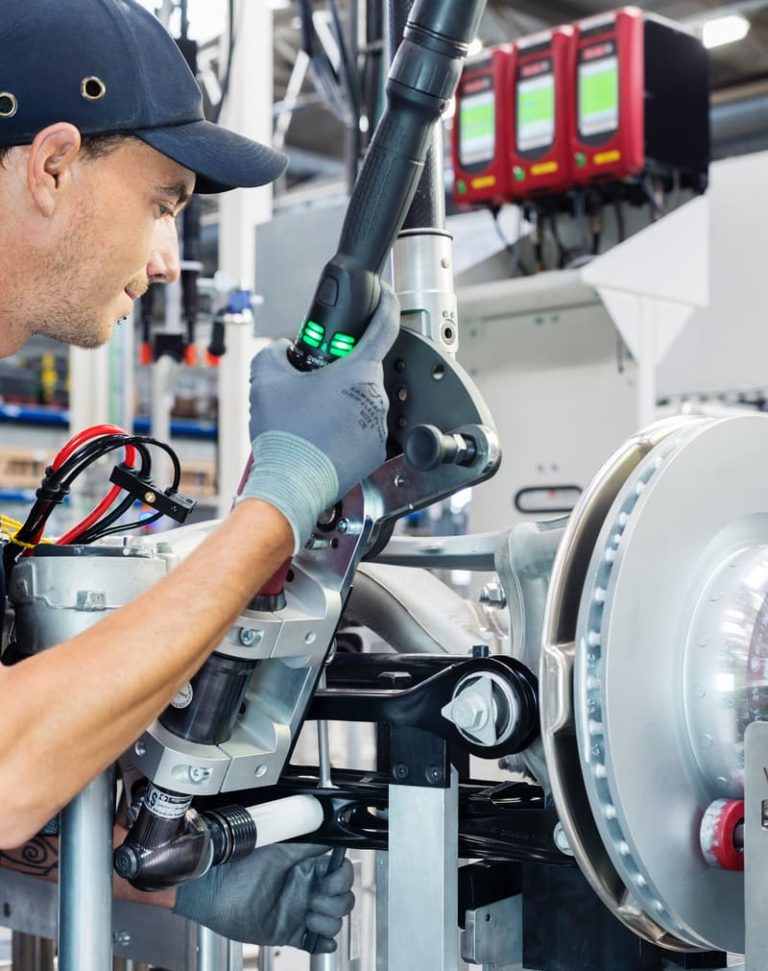

Driven by a servo motor, the servo press uses software to control press speed and position, making this product more flexible than a conventional mechanical press. The servo press features a closed-loop feedback system to accurately control cycle rate and loads, which provides the ability to apply very high forming loads early in the stamping stroke. System configuration is straightforward, consisting of a tool, controller and cable. Precision control of load, position, speed and time combine to increase productivity. Servo presses are environmentally friendly — the servo driven motor translates into reduced energy consumption and less noise. Added benefits are the adjustable stroke, increased speed and cycle rates, improved part quality, longer tool life and better equipment uptime. Programming is easy and intuitive, and user-friendly parameter input facilitates quick setup. Real-time reporting of operating conditions greatly reduces the risk of damage to parts. The extensive range of data collected provides full traceability.

Let Us Walk Your Line & Revolutionize Your Process

We Don't Just Know Products - We Know Applications

Why Choose Rhino Tool House?

Rhino Tool House is the leader in cordless assembly solutions. Our highly trained and experienced team is available to visit your facility to help you

determine how and where cordless technology is best suited for your specific needs and manufacturing environment. We also help train your team on the use and maintenance of this technology. Start utilizing

battery-operated tools today and realize the benefits of improved quality, safety and productivity.