DC ELECTRIC ASSEMBLY TOOLS

Precision Handheld Tools from the World’s Top Manufacturers

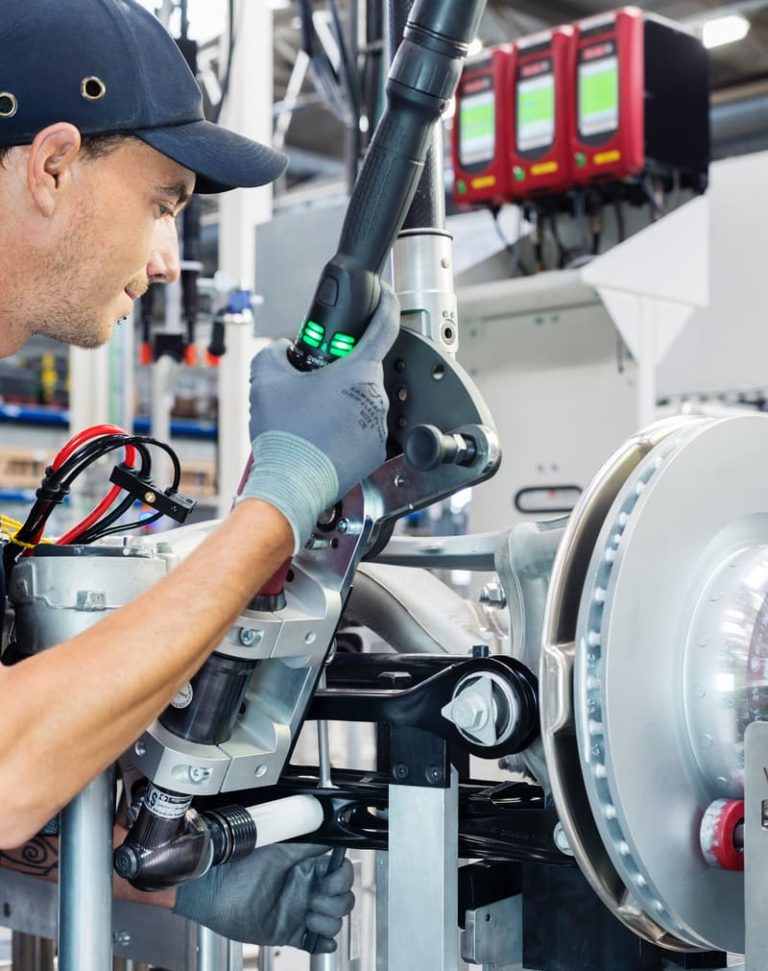

In today’s market, our customers require “near-zero” product defects during the assembly process. Our electric handheld nutrunners allow you to control, manage and document each step in the assembly of your product. Rhino Tool House tools will meet your torque requirement from extremely low to very high torque applications in the automotive, off-road vehicle, heavy truck, electric component, aerospace, consumer appliance and electric vehicle markets. Rhino Tool House offers a variety of handheld electric nutrunners and screwdrivers for applications in which ergonomics, accuracy, quality control and speed are critical. Made by top manufacturers, our durable DC electric tools save time in the tightening process while ensuring that the job is done right the first time.

Fixtured DC Electric Tools

Rhino Tool House offers fixtured spindles in an array of configurations to meet your assembly and throughput requirements. With 1 up to 32 spindle multi systems available, we provide a custom turnkey solution to meet your sophisticated fastening requirements while helping you increase productivity, throughput, quality, and reduce labor costs. A mounted, fixtured electric spindle is used in semi-automatic or automatic operations. When properly sized and configured, a fixtured multi-spindle system provides the highest level of performance and quality. There are advantages with multi-spindles that are not available in any other tightening solutions.

Let Us Walk Your Line & Revolutionize Your Process

We Don't Just Know Products - We Know Applications

Why Choose Rhino Tool House?

Rhino Tool House is the leader in cordless assembly solutions. Our highly trained and experienced team is available to visit your facility to help you

determine how and where cordless technology is best suited for your specific needs and manufacturing environment. We also help train your team on the use and maintenance of this technology. Start utilizing

battery-operated tools today and realize the benefits of improved quality, safety and productivity.