Manual Click Wrenches

Manual Click Wrenches

Numerous product recalls are due to fasteners not being correctly torqued. Auditing and/or controlling torque during the assembly process is an essential step in ensuring a product’s quality, safety and reliability. Many Rhino Tool House manufacturing customers strive to achieve “zero” product defects. A tool that allows them to control, manage and document each step in their product assembly helps them reach that lofty goal.

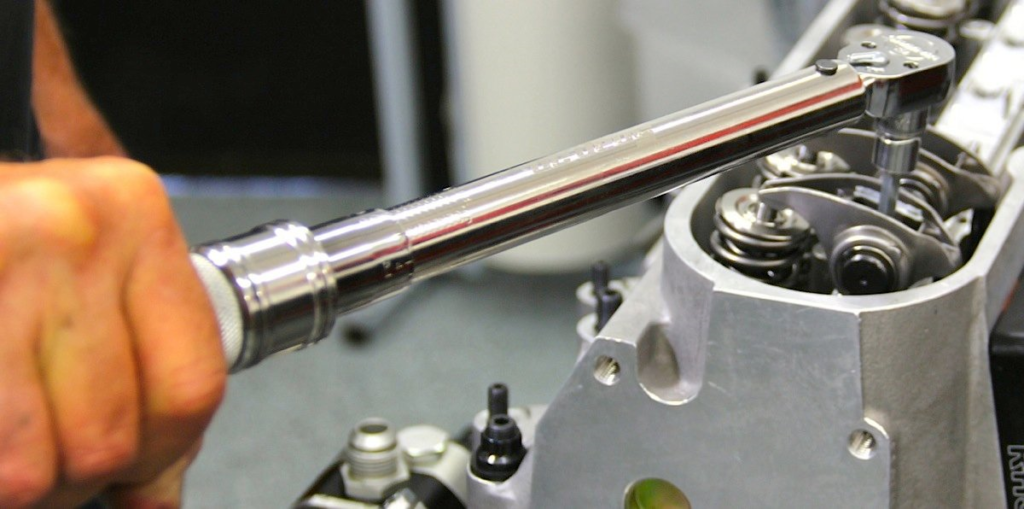

The click wrench applies a specified torque to a fastener, ensuring that the fully assembled product meets quality, safety and reliability standards. The mechanical click torque wrench accomplishes this task. The click wrench is calibrated and preset to a specified torque value. When that value is reached, the wrench clicks and produces audible and tactile signals. The signals allow the operator to determine the existence of a pass or fail condition. Digital click wrenches have become popular due to the capabilities and requirements of quality and process engineers. This type of wrench provides a greater degree of accuracy along with SPC software and data storage.

Benefits of Digital Click Wrenches

- Speed, accuracy, precision, memory recall, and an easy-to-read display

- Wireless transmission capability

- SPC data storage

- Reduces operator error

- Multiple engineering units of measurement in one wrench

Let Us Walk Your Line & Revolutionize Your Process

We Don't Just Know Products - We Know Applications

What Sets Rhino Tool House Apart for Manual Click Wrenches?

We are experts in blind rivet and rivet nut Installation tooling. We address our customers’ needs by leveraging our team’s collective knowledge and our chosen supplier base of innovative power tool and automated tool solutions. We invite you to reach out to your local Rhino Tool House sales engineer for a consultation and needs assessment. Close collaboration with our customers allows us to understand their needs and specify the right solution — the first time and every time. Reach out today!