Our Priorities Are Your Priorities

Your

Productivity

At its most basic, productivity is a simple measurement – what are your inputs and, conversely, what are your outputs? Your inputs include any resources — such as your people, tools, raw materials, energy, and finance — that you use in your manufacturing plant to get the desired output. Resources are often financial, but things like time and expertise are also considered inputs.

Your outputs are of course your products which are produced by your machines, your people, and your process.

So it’s simple, right? You want to be more successful? Then improve your productivity.

Well, that is, as they say, sometimes easier said than done.

With more and more to do and fewer resources to do it, its harder than ever to stay on top of the latest manufacturing trends and technologies that are emerging to help make you more successful.

That’s where Rhino Tool House comes in. Where other companies who claim to want to help you by selling you tools, Rhino Tool House does more. Rhino Tool House works with you to help analyze your current situation and find better solutions to improve the effectiveness and efficiency of your manufacturing operations.

If you simply want a new or replacement tool, we’ve got that too. In fact, Rhino Tool House works hard to make sure we partner with the world’s leading tool manufacturers so that when you turn to Rhino Tool House, you’ve turned to the company who has not only the broadest selection of tools there is, we have the latest technologies focused on improving your productivity. We even have our own manufacturing resources to round out our entire line.

Your

Quality

MANUFACTURING QUALITY

Some things go without saying. Things like – “quality is important.” Still we’re going to say it anyway. “Quality in any manufacturing environment is important.”

There is no way around it: the cost of poor manufacturing quality is really, really high. Think about product failures and what it does to your process, your company, you profit, the very environment in which you work.

And quality issues are kind of a vicious cycle. They can be caused by inefficiencies, delays, breakdowns, inferior resources, worker failure, and myriad other factors. Quality issues can cause inefficiencies, delays, and, most significantly, customer dissatisfaction. These are the obvious ramifications, but what about worker dissatisfaction as well as a deterioration of shareholder confidence.

Today more than ever, you as a modern manufacturer must build good, quality products, build them on time, the first time and every time to achieve the profits, the confidence, the success you need.

Rhino Tool House can help. If quality issues are on the rise, we can work with you today to find the problems and help incorporate meaningful solutions that get results. Even if your quality measures show you are right about on track, you can almost certainly still do better. Let Rhino Tool House walk with you in your plant, look over your line and listen carefully to you as you discuss your biggest challenges.

We are very good at what we do – and we would be honored to let us work with you.

Your

Safety

Probably not.

You care deeply about your employees and do all you can to ensure the physical well-being of the workers throughout your manufacturing facilities.

The problem is, sometimes the concept of a safe work environment is highly complex in practice, encompassing multiple disciplines, processes, and technologies.

At Rhino Tool House, we stay on top of the latest tool technologies and innovations – those designed to not only make you more productive – but those that help make sure your entire team remains safe and healthy while performing their tasks.

The use of wearables such as exoskeletons, for example, can not only preclude the need to make extensive changes to your work environment, but these devices may also be exactly what you need to improve workplace safety and efficiency!

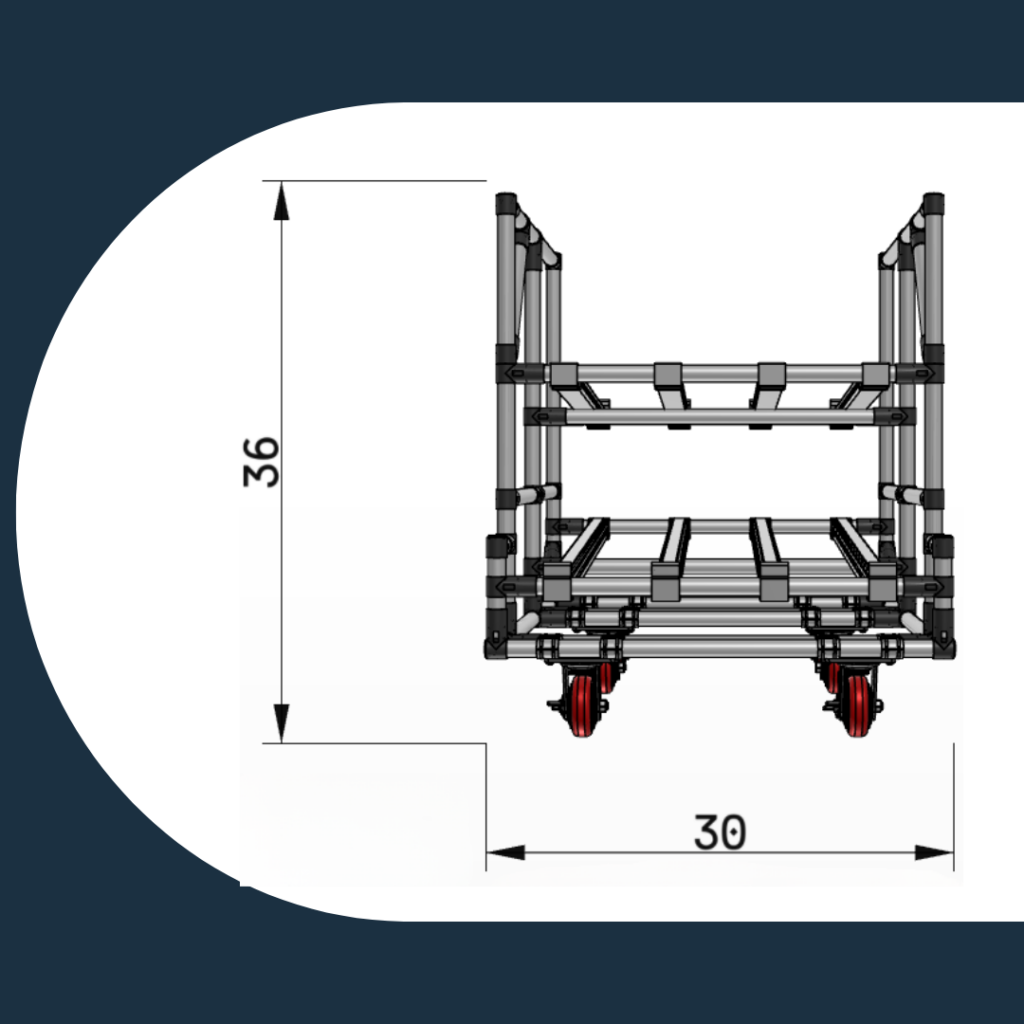

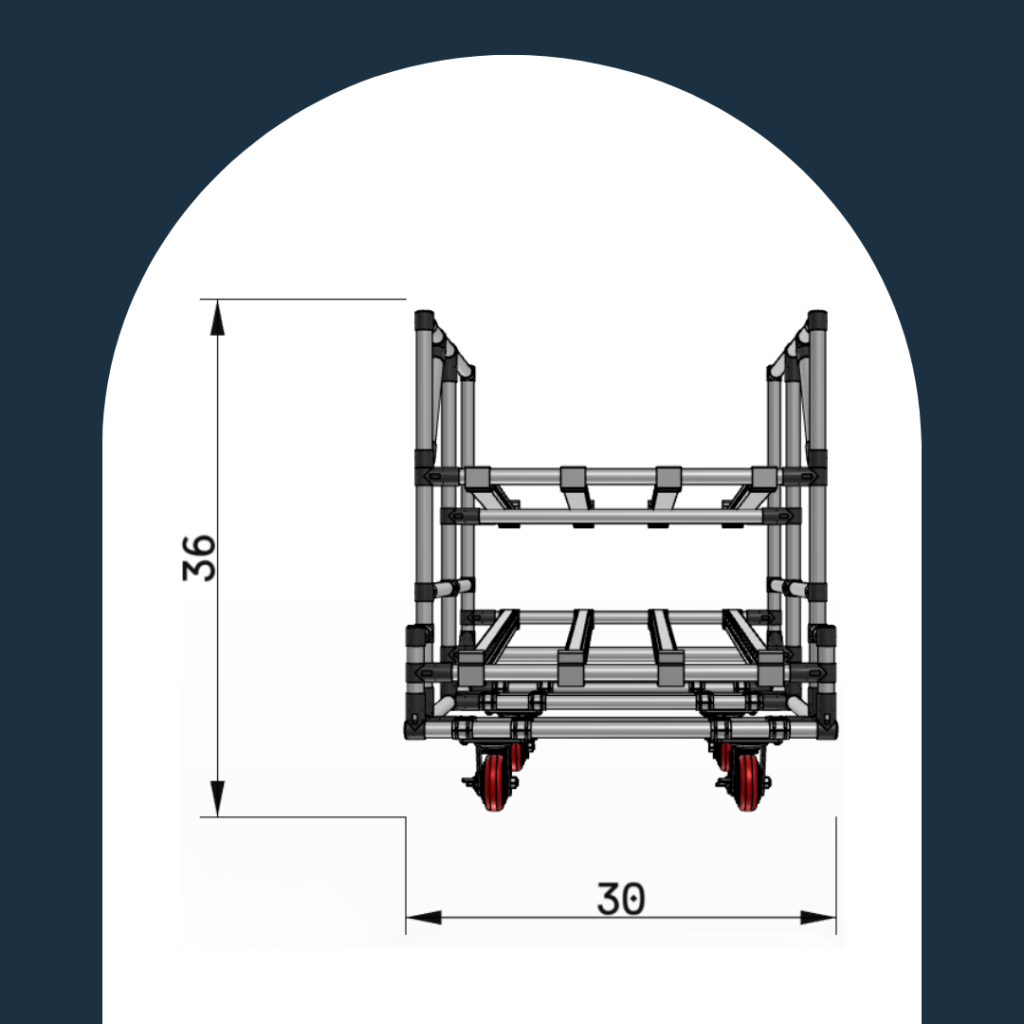

We want to work closely with you to help make sure that, while helping reach the next level with floor-to-ceiling manufacturing solutions, we also work with you to help create the safest workplace possible. We specialize in cranes, conveyors, manipulators, hoists and other lifting devices, racking, automated guided vehicles, carts, lift tables, turntables, and other products where their reliability and effectiveness go hand-in-hand with safety considerations.

Take advantage of Rhino Tool House’s extensive product knowledge and experience in manufacturing process improvement and let us help you Revolutionize Your Process today.