By Jonathan Paul – Robotics Product Manager, Rhino Tool House

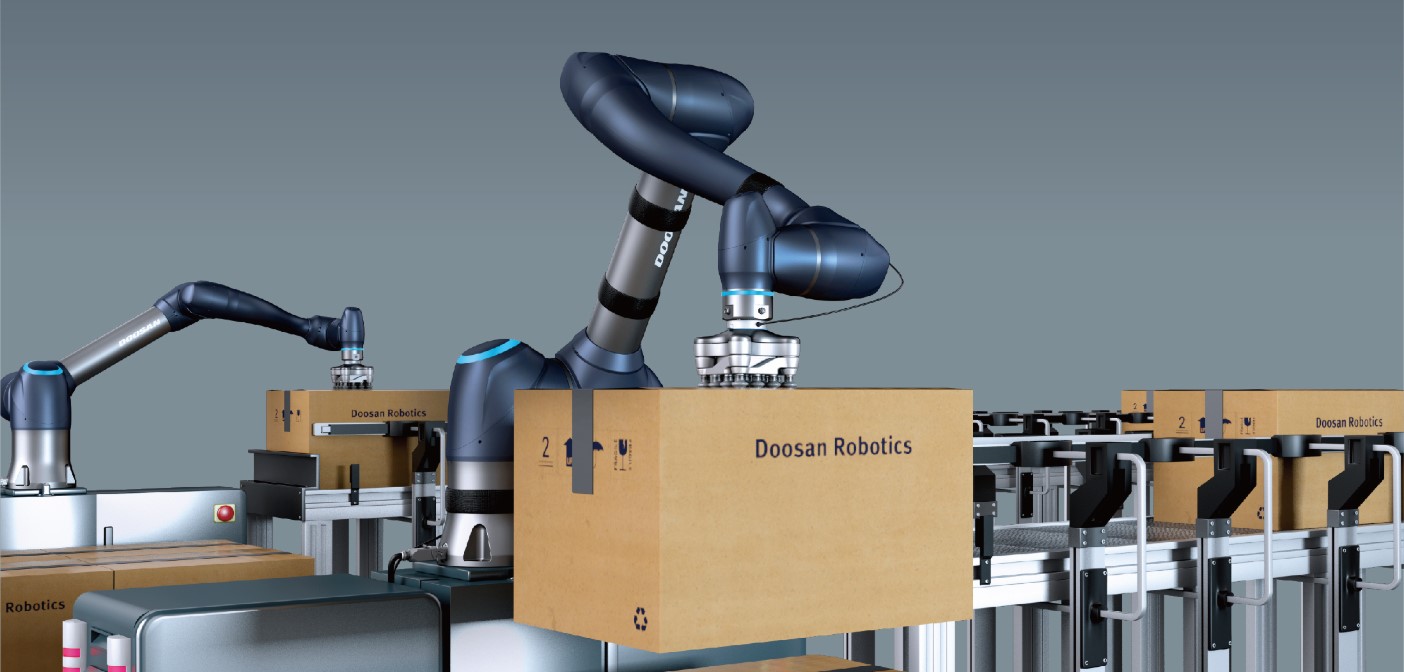

In today’s competitive climate of modern manufacturing, does anyone still doubt that incorporating collaborative robots into your manufacturing process is a good idea?

Probably not!

But at Rhino Tool House, we find that many operations professionals still have a perception that “complexity” is an issue and that incorporating a cobot just isn’t worth it in the long run.

These are the concerns we hear the most, followed by how we tend to respond.

Safety over speed –

We often hear concerns in high-speed applications, such as sorting or packaging, that a cobot will need to move too slow to be safe.

However modern cobots can calculate an alternative route allowing them to carry on with their task in a safe way, without having to compromise productivity. Multiple Cobots can work in tandem and are capable of real time communication to one another, allowing for multiple cobots working on the same tasks. Safety hardware can easily be integrated as a plug and play type of device.

Precision questions –

For example, in bin-picking, where objects aren’t necessarily found in a precise location, picking is more challenging.

But today modern vision systems and “machine learning” enables cobots to bin-pick random parts with unprecedented precision, with simple integration learning.

Many fixtures/parts are not an exact measurement. Rhino Tool House offers numerous cameras, sensors, and hardware devices to improve any accuracy problems you may have.

Flexibility –

The perception is that product variation adds complexity and a cobot programmed for one application won’t work for another.

But programming is easier than ever before, and across its life cycle most cobots perform in multiple applications within a given plant over many years. Cobots have a user-friendly GUI interface for easy of programming. Programming can still be performed the more traditional way if it is desired.

Despite these concerns and several others, collaborative robots have become almost as common as industrial robots, with companies citing increased productivity, improved quality, and safety as the primary reasons for incorporating them.

Call your nearby Rhino Tool House manufacturing expert to see how collaborative robots can be applied in your operation.