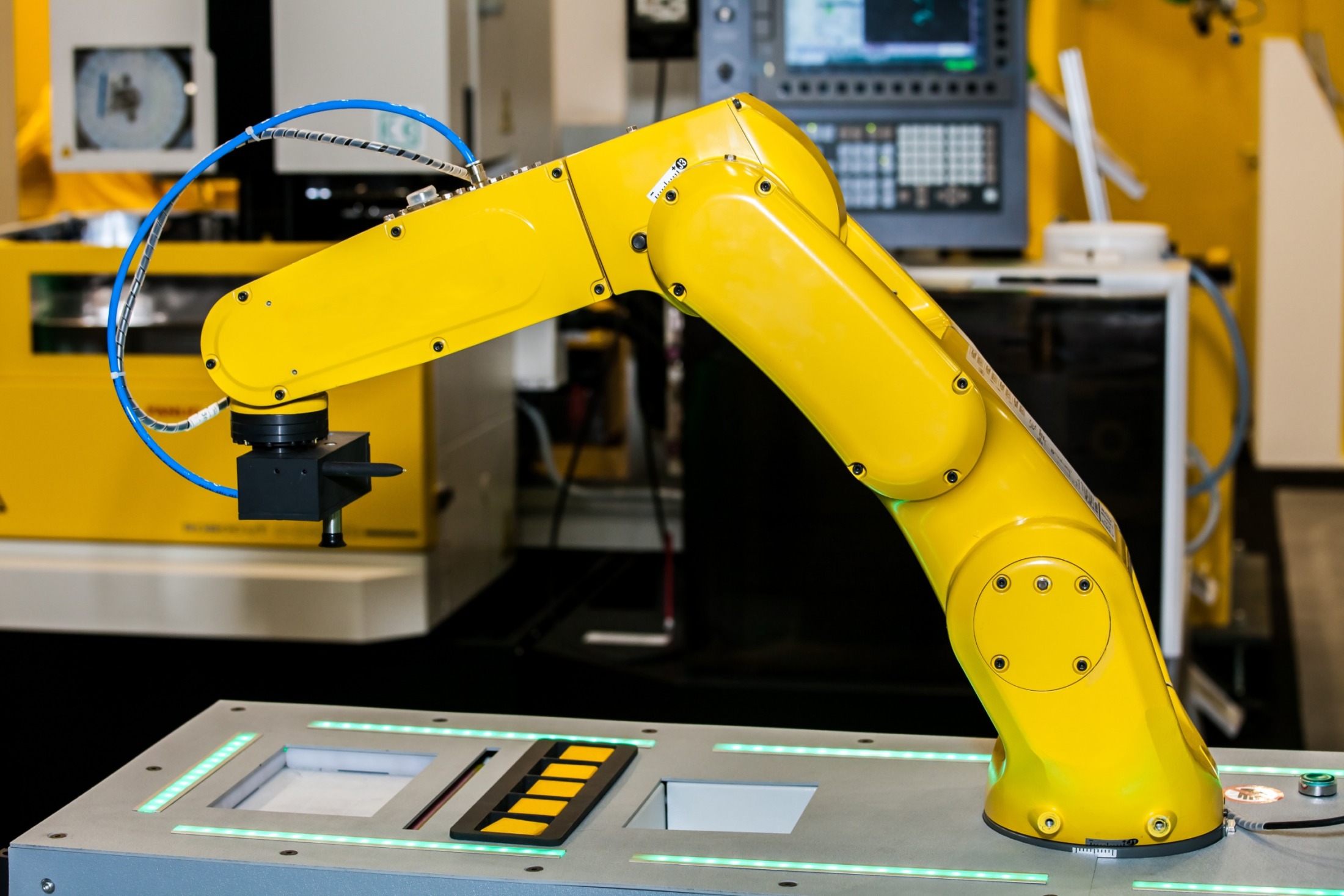

Collaborative robots, also known as cobots, have revolutionized the manufacturing industry by introducing a new level of efficiency, flexibility, and safety. These robots are designed to work alongside human workers, collaborating on various tasks and augmenting human capabilities. Rhino Tool House recognizes the value of collaborative robots and offers comprehensive planning and implementation solutions to its customers, ensuring they can harness the benefits of cobots in their manufacturing processes.

Increased Productivity

One of the key benefits of collaborative robots is increased productivity. Cobots can perform repetitive and mundane tasks with consistent precision and speed, leading to improved production rates. By automating such tasks, human workers can be freed up to focus on more complex and value-added activities, enhancing overall efficiency.

Workplace Safety

Collaborative robots also enhance workplace safety. Traditional industrial robots are typically large, powerful machines that require physical barriers to separate them from human workers. In contrast, cobots are designed to operate safely alongside humans, featuring advanced sensors and intelligent algorithms that allow them to detect and respond to human presence. This collaborative nature reduces the risk of accidents and injuries, creating a safer work environment.

Flexible and Adaptable

Another advantage of cobots is their flexibility and adaptability. These robots can be easily programmed and reprogrammed to perform different tasks, allowing manufacturers to quickly switch between product lines or make adjustments to their processes. This flexibility is especially beneficial in dynamic manufacturing environments where rapid changes and customization are required.

Planning and Implementation

Rhino Tool House excels in supporting its customers with planning and implementing collaborative robots. They have a team of experts who possess in-depth knowledge of cobots and understand their integration into diverse manufacturing operations. Rhino Tool House collaborates closely with their customers to assess their specific requirements, identify suitable cobot applications, and develop customized solutions.

Training and Support

Moreover, Rhino Tool House offers training and support services to ensure a smooth transition and efficient utilization of cobots. They assist their customers in selecting the right cobot models, designing the layout for optimal workflow, programming the robots to perform desired tasks, and integrating them with existing systems. Their expertise helps manufacturers optimize their processes, increase productivity, and achieve a higher return on investment.

In summary, collaborative robots bring numerous benefits to the manufacturing process, including increased productivity, enhanced workplace safety, and improved flexibility. Rhino Tool House plays a vital role in supporting its customers by providing expert guidance in planning and implementing cobots. With their comprehensive solutions and support, Rhino Tool House helps manufacturers harness the power of collaborative robots and stay ahead in today’s competitive industrial landscape.