YOU CAN TRUST US TO HELP YOU “TAME” YOUR PRODUCTION ASSEMBLY LINE WITH THE RIGHT TOOLS TO HELP MAKE YOU MORE ACCURATE, CONNECTED AND SAFE

Rhino Tool House and Cleco stand together with you to help you find solutions that are as durable as they are precise and as reliable as they are innovative.

Use the form below to schedule a call today.

Success Stories

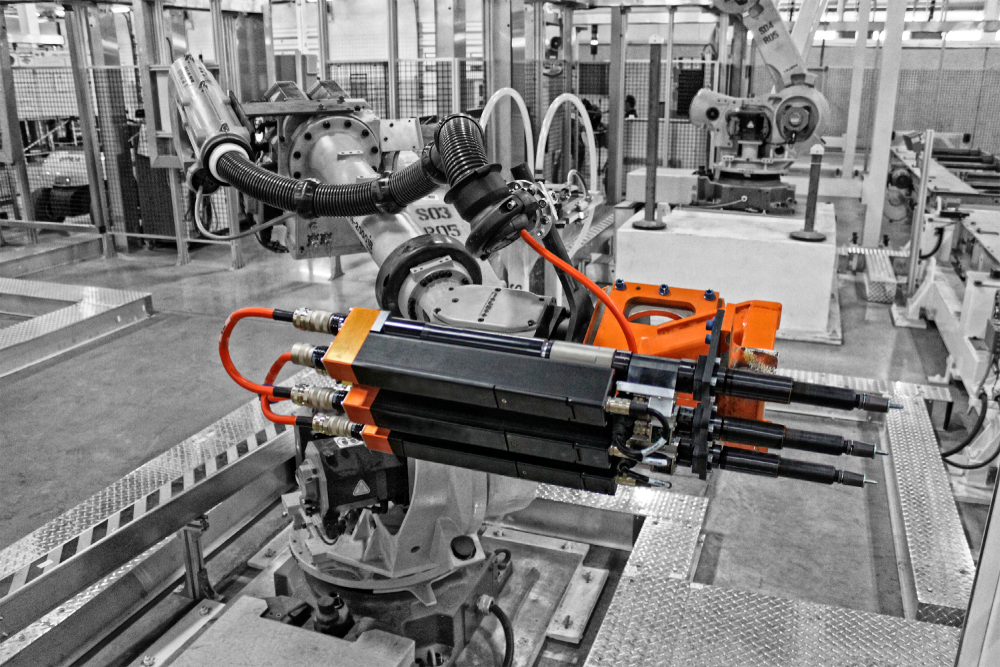

Rhino Tool House and Cleco Speed Production with Intelligent Spindles

Keeping the line running is critical to a healthy manufacturing process, but using the wrong tools on the line can put the schedule at risk.

Rhino Tool House partnered with a leading manufacturer who was looking for a reliable and efficient fastnening system that could perform over 1 million rundown cycles per year/per tool. The tool needed to be reliable, durable enough to last with limited maintenance and low risk of failure.

The customer evaluated several assembly tool brands, and chose Cleco Intelligent Spindles for the application involving tightening of valve covers. The customer was impressed by Cleco’s full portfolio offering, demonstrated expertise delivering value to leading global manufaturers, and Rhino Tool House’s full service solution.

Following installation of (8) Cleco Intelligent Spindle systems, the manufactuer has observed increased production output and virtually failure-free durability, delivering on the original promise made.

Contact a Rhino Tool House Sales Engineer today to learn how we can help make your line more productive.

Rhino Tool House and Cleco Deliver Cost-Effective, High-Torque Cordless Tool Solution

Manufacturing Engineers are looking for convenient battery-powered assembly tools that deliver ergonomics without compromising high torque output. Common alternatives are DC electric tools that deliver the torque requirements and ergonomics but include cables that can be costly to maintain and increase risk of slips, trips & falls.

Rhino Tool House worked with Cleco to demo their CellCore Cordless Right Angle Nutrunner, an ergonomic cordless tool that reduces operator fatigue without compromising torque output. CellCore’s large user interface allows easy on-the-tool programming without a controller, reducing overall tool costs and boosting operator efficiency.

Cleco’s solution delivered on the manufacturing customer’s needs for an ergonomic cordless tool, with the reaction bar to provide operator safety and comfort at high torque (90nm). Rhino Tool House’s expert Sales Engineers were on hand to support a seamless install, which led to a smooth line transition and excellent results for the customer. The Manufacturing Engineer is impressed by how little space is used by the CellCore tool, and how the stringent in-house ergonomic standards were exceeded by the tools.