Material Handling

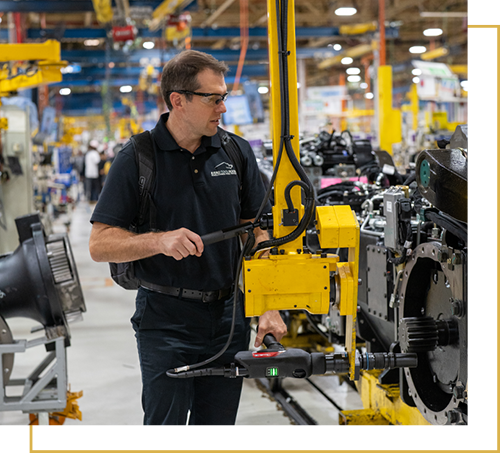

Material Handling Solutions That Move Your Operation Forward

At Rhino Tool House, we help manufacturers improve workflow, reduce strain, and move materials more efficiently with tailored material handling solutions. Whether you need carts, conveyors, cranes, or a fully integrated system, we source from top vendors and design around your process—not the other way around.

From simple transport to complex automation, our team ensures the equipment fits your space, your people, and your production goals.

What You Can Expect

Smarter Movement

We offer a full range of carts, conveyors, overhead systems, and flow racks to streamline how materials move on your floor—improving ergonomics and throughput.

Tailored Engineering Support

Our in-house team audits your workflow and recommends right-sized solutions, from modular carts to custom storage systems and integrated automation.

Multi-Vendor Access, Single-Source Simplicity

We’re not tied to one manufacturer, so we recommend what’s best for you—and handle everything from design to installation.

Industries We Support

Automotive

Aerospace

Electronics

Medical Devices

Consumer Goods

And more!

Request Your Free Estimate Today!

Customer Success Story

Let’s Build a System That Works for You

Ready to move materials more efficiently? Our team can help you get there.